In industrial projects, calcium chloride is rarely chosen by chance. Selecting the wrong grade, concentration, or application method can increase operating costs, reduce system efficiency, and create long-term maintenance issues. For this reason, calcium chloride is not simply a commodity chemical—it is a functional process material that directly affects project performance.

Understanding the uses of calcium chloride in industry requires looking beyond basic definitions and focusing on how this compound behaves under real-world operating conditions.

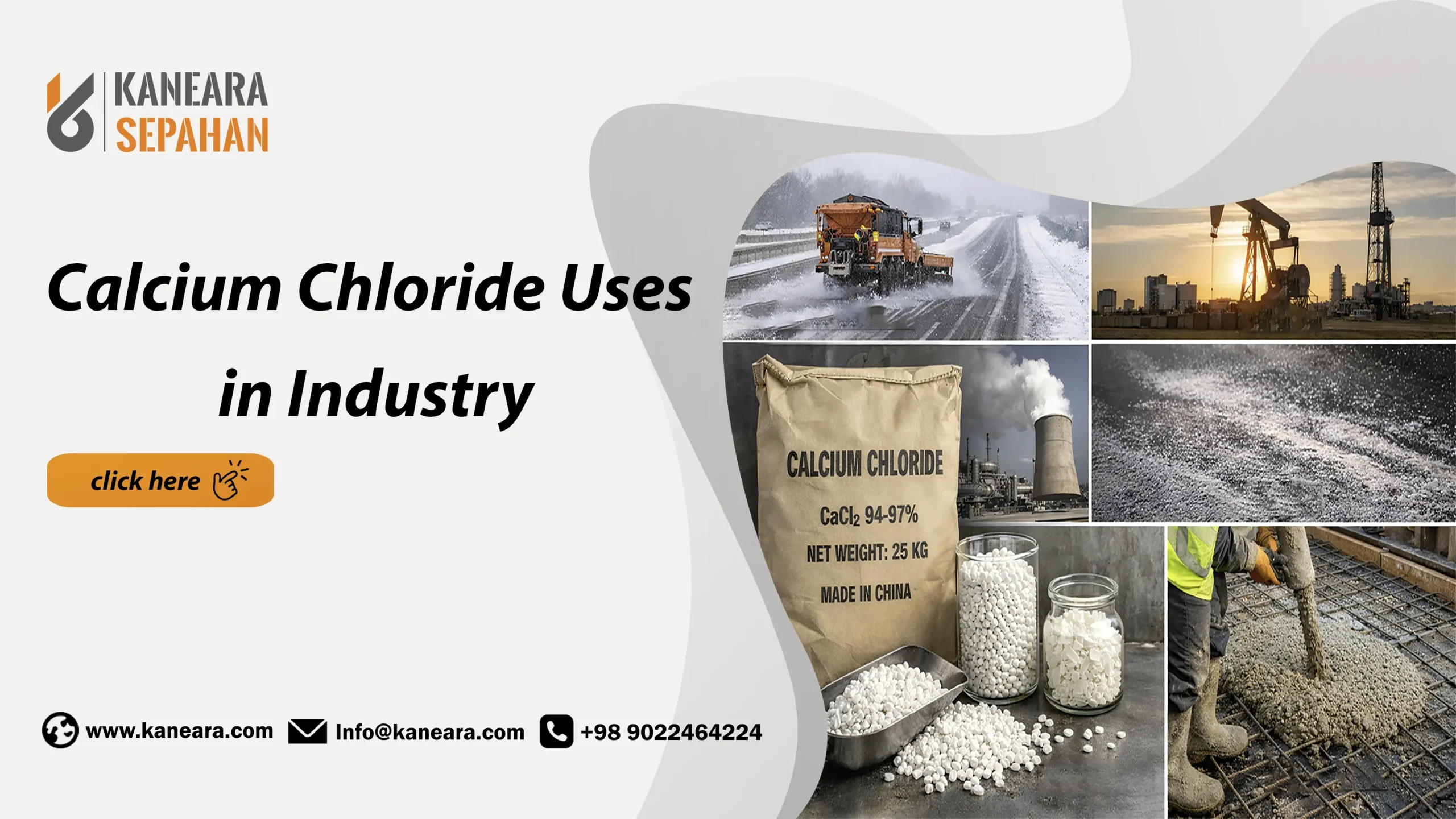

From construction sites and water treatment plants to road maintenance and industrial facilities, calcium chloride is used to control moisture, accelerate reactions, stabilize materials, and improve operational reliability.

This article is written for industrial buyers, engineers, contractors, and procurement managers who need a practical understanding of where and how calcium chloride is used—and how to choose the right specification for each application.

Construction is one of the largest consumers of industrial calcium chloride. Its role in this sector is tied directly to productivity, quality control, and project scheduling.

Concrete Acceleration and Project Timelines

In concrete applications, calcium chloride is used primarily as a setting and strength accelerator. This is especially critical in cold-weather construction, where low temperatures slow cement hydration and increase the risk of freezing.

From a B2B perspective, calcium chloride in construction helps:

However, improper dosage or grade selection can lead to corrosion risks in reinforced concrete. This is why experienced contractors treat calcium chloride as a controlled additive, not a generic accelerator.

Dust Control on Construction and Access Roads

Dust generation is a major operational and environmental concern on construction sites, quarries, and temporary roads. Calcium chloride’s hygroscopic nature allows it to attract and retain moisture, binding fine particles to the surface.

Industrial users apply calcium chloride to:

Compared to water-only dust control, calcium chloride provides longer-lasting results, reducing repeated application costs.

Soil Stabilization and Compaction

In road building and foundation preparation, calcium chloride improves soil compaction by maintaining optimal moisture levels. This results in stronger subgrades and reduced maintenance over time—an important consideration for infrastructure projects with long service lives.

Among the most technically sensitive industrial calcium chloride applications is water and wastewater treatment. In this sector, performance consistency and chemical compatibility are critical.

Water Hardness and Corrosion Control

Calcium chloride water treatment applications often focus on adjusting calcium ion levels to stabilize water chemistry. Proper hardness balance helps protect pipes, pumps, and heat exchangers from corrosion and scaling.

For industrial facilities and municipalities, calcium chloride contributes to:

Wastewater Treatment and Sludge Processing

In wastewater operations, calcium chloride supports chemical precipitation and sludge conditioning. It enhances floc formation, improving solid-liquid separation during sedimentation and filtration.

From a procurement standpoint, the purity and solubility of calcium chloride directly affect treatment efficiency and chemical consumption rates.

Process Stability and Compliance

Because calcium chloride does not significantly raise alkalinity, it is often preferred in processes where pH control is sensitive. This makes it suitable for specialized industrial treatment systems operating under regulatory constraints.

Calcium chloride deicing is one of the most widely recognized industrial uses, but its value lies in performance under extreme conditions—not just ice melting.

Performance in Low-Temperature Environments

Unlike sodium chloride, calcium chloride remains effective at much lower temperatures. Its exothermic dissolution releases heat, accelerating ice melting even in severe winter conditions.

This makes calcium chloride the preferred choice for:

Cost Efficiency through Reduced Application

Although calcium chloride may have a higher unit cost, it often requires lower application rates. For large-scale operations, this can result in lower overall material usage, reduced labor, and less infrastructure damage.

Multi-Season Utility

Beyond winter maintenance, the same calcium chloride products are commonly used for dust suppression on unpaved roads during dry seasons, improving year-round asset utilization.

Calcium chloride’s functional versatility extends into several additional industrial sectors.

Chemical Processing and Manufacturing

In chemical plants, calcium chloride is used as a processing aid, drying agent, or reaction component. Its predictable behavior and availability in multiple forms make it suitable for controlled industrial processes.

Oil and Gas Operations

Calcium chloride brines are widely used in drilling and completion fluids. They help control formation pressure, stabilize shale formations, and protect wellbore integrity. In this context, solution concentration and purity are critical performance factors.

Refrigeration and Heat Transfer Systems

Calcium chloride solutions are used in industrial cooling and refrigeration systems as secondary refrigerants—their thermal stability and cost efficiency support large-scale temperature control applications.

For industrial buyers, price evaluation should always be aligned with technical specifications rather than considered in isolation.

Factors such as purity level, physical form, packaging, and logistics all influence the final calcium chloride price per ton, especially for bulk and export-oriented projects.

Common Industrial Forms

Key Selection Criteria

When evaluating calcium chloride uses in industry, procurement, and technical teams should consider:

In many industrial projects, selecting the right calcium chloride grade requires technical evaluation rather than price comparison alone.

Calcium chloride plays a strategic role across multiple industries, from construction and infrastructure to water treatment and energy. Its effectiveness depends not only on the material itself but on how well it matches project-specific requirements.

For large-scale, export-oriented, or technically sensitive applications, industrial buyers benefit most from working with suppliers who understand both material specifications and real-world operating conditions.

When calcium chloride is selected correctly, it becomes a cost-effective, performance-enhancing component of industrial systems—not just another chemical input.

Kane Ara Sepahan Company, with over 20 years of experience in the extraction, processing, and export of mineral materials, is one of the leading and reputable direct producers and suppliers in Iran. Our technical expertise, extensive international network, and integrated supply chain ensure the reliable delivery and sustainable supply of products to customers both domestically and internationally.

No. 40, Fifth Street, Opposite Third Alley, Phase 1, Segzi Industrial Town, Isfahan, Iran

3rd Floor, No. 12, Dead End, Alley 31, Before Abolhasani Esfahani Crossroad, Sharif Vaghfi Street, Isfahan, Iran