The oil bleaching process is a critical stage within edible oil refining steps, positioned between degumming/neutralization and deodorization. From a process engineering perspective, bleaching is not simply about visual color improvement.

It is a controlled adsorption-based oil purification method designed to remove a wide spectrum of undesirable compounds that affect oil stability, safety, and downstream processing performance.

In industrial edible oil production, crude oils extracted from oilseeds or fruits contain pigments, trace metals, oxidation products, soaps, phospholipids, and thermal degradation by-products.

If these impurities are not effectively removed before deodorization, they can compromise final oil quality, reduce deodorizer efficiency, and accelerate oxidative deterioration during storage.

This article explains how the oil bleaching workflow operates in practice, why it is necessary, and how bleaching earth usage—particularly activated bentonite—fits into the overall refining strategy from an operational and quality-control standpoint.

In the sequence of edible oil refining steps, bleaching performs functions that cannot be fully compensated for by upstream or downstream operations.

While degumming and neutralization remove the bulk of phospholipids and free fatty acids, they do not adequately address pigments, trace metals, or oxidation by-products.

Crude vegetable oils naturally contain pigments such as:

These compounds are the primary targets of the oil decolorization process. Chlorophyll derivatives are particularly problematic because they act as photosensitizers, accelerating oxidative reactions when oil is exposed to light. Even low residual concentrations can significantly reduce shelf life.

Bleaching removes these pigments through adsorption rather than chemical transformation, preserving the triglyceride structure of the oil while improving visual and oxidative quality.

Trace metals such as iron and copper enter the oil from:

Although present at ppm or sub-ppm levels, these metals catalyze peroxide formation and secondary oxidation reactions. The oil bleaching process is one of the most effective stages for removing these catalysts, particularly when activated bentonite is used.

Bleaching also targets:

From an operational perspective, these polar compounds are responsible for:

Thus, bleaching is not an optional refinement but an essential oil purification method that stabilizes the oil before high-temperature treatment.

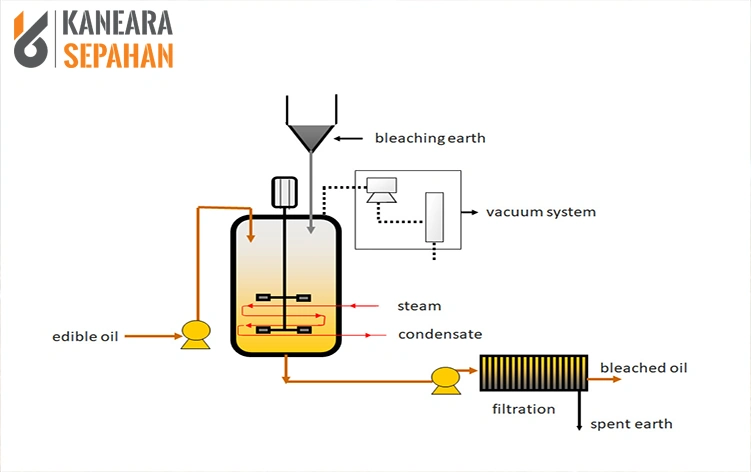

Although equipment layouts vary by refinery size and oil type, the oil bleaching process follows three fundamental stages. Each stage must be carefully controlled to ensure adsorption efficiency without excessive oil losses.

Bleaching begins with thermal conditioning of the oil. Temperature and moisture control at this stage directly affect adsorption kinetics and filterability.

Typical Operating Conditions:

Heating reduces oil viscosity, improving mass transfer between the oil phase and bleaching earth. Insufficient heating results in poor dispersion of adsorbent particles, while excessive temperature may accelerate oxidation if oxygen ingress is not properly controlled.

From operational experience, inconsistent heating profiles are a common cause of batch-to-batch color variation, especially in batch bleaching systems.

This stage defines the effectiveness of the oil decolorization process. Bleaching earth usage typically involves activated bentonite clay, selected for its high surface area and controlled pore structure.

Role of Activated Bentonite: Activated bentonite is chemically treated to enhance its adsorption capacity for:

The clay is dosed into the hot oil and mixed under a vacuum or an inert atmosphere. Vacuum conditions are preferred because they:

Typical dosage ranges from 0.5 % to 2.5 % by weight, depending on crude oil quality and target color specifications.

Operational insight: Overdosing does not linearly improve bleaching efficiency. Beyond a certain point, additional clay increases oil retention in spent earth and raises filtration costs without proportional color improvement.

This decision point is where refinery engineers often adjust clay type, activation level, and dosage to balance performance, oil loss, and operating cost.

After sufficient contact time (typically 20–40 minutes), the oil-clay slurry is filtered to remove spent bleaching earth along with adsorbed impurities.

Filtration Systems Commonly Used:

Effective filtration requires:

Poor filtration performance is frequently linked to:

From a plant reliability standpoint, filtration bottlenecks are often more disruptive than bleaching inefficiency itself, underscoring the need for integrated process control.

Bleaching efficiency is not solely determined by adsorbent selection. It results from the interaction of multiple process variables that must be optimized together.

Higher levels of:

Increase bleaching earth consumption and reduce filter run length. In practice, improving upstream degumming often yields greater cost savings than increasing clay dosage.

Not all activated bentonites perform equally. Key properties include:

Highly activated clays provide strong color removal but may increase oil retention and free fatty acid formation if misapplied.

Adsorption is temperature-dependent. However:

Experienced operators strive for the lowest temperature that consistently achieves the target color.

Even optimal adsorption is ineffective if filtration fails. Uniform cake formation and stable pressure profiles are essential for maintaining throughput and minimizing oil losses.

The oil bleaching process is a technically demanding yet indispensable step within edible oil refining. Far from being a cosmetic operation, bleaching is a core oil purification method that directly affects product stability, safety, and refinery efficiency.

By understanding the interactions between heating, adsorption using activated bentonite, and filtration, refinery engineers can optimize bleaching earth usage, reduce operating costs, and improve final oil quality. Successful bleaching is always the result of system-level optimization rather than isolated parameter adjustments.

Kane Ara Sepahan Company, with over 20 years of experience in the extraction, processing, and export of mineral materials, is one of the leading and reputable direct producers and suppliers in Iran. Our technical expertise, extensive international network, and integrated supply chain ensure the reliable delivery and sustainable supply of products to customers both domestically and internationally.

No. 40, Fifth Street, Opposite Third Alley, Phase 1, Segzi Industrial Town, Isfahan, Iran

3rd Floor, No. 12, Dead End, Alley 31, Before Abolhasani Esfahani Crossroad, Sharif Vaghfi Street, Isfahan, Iran