What is bentonite uses?

Bentonite and bentonite uses , a type of absorbent and clay-rich rock, has found its way into numerous industries due to its versatile properties. This natural

Thermal solutions and magma that have specific chemical compounds lead to the formation of barite in faults, fractures, and the empty space between particles and pieces of rock. Along with some thermal deposits of silver, lead, zinc, and fluorite, barite is also seen. Barite was first discovered in Romania.

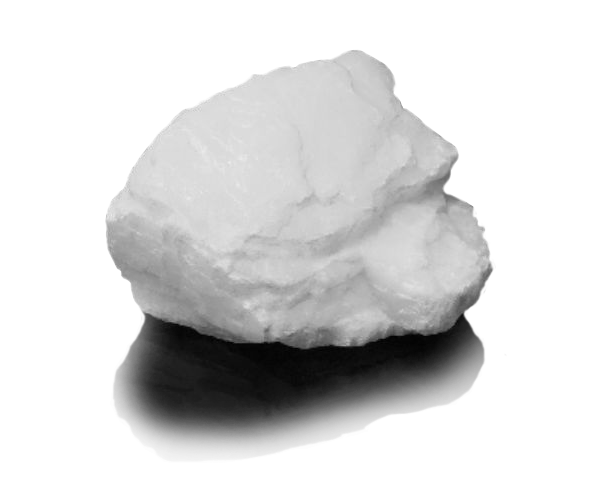

Barite is one of the most widely used minerals in various industries, which can be found in nature as streaks or layers. This material is very heavy and its color is mainly milky white. The more impurities in this material, the more colorful it can be. In this case, the range of barite colors is from milky white to red, brown, yellow, and purple.

Due to its different properties and characteristics, this mineral is used in micro-ionized or mineral form in various industries. The most important properties of barite are listed below:

| Specific gravity | gr/cm3 | min 4.20 |

| Soluble alkaline earthmetals calcium | ppm | max250 |

| Viscosity | cps | max125 |

| Residue on ASTM sieve no: 325 | w.t % | max15 |

| Residue on ASTM sieve no: 200 | w.t % | max3 |

| Less than 6 μm | w.t % | max30 |

Large barite ore is crushed into smaller sizes by a small jaw crusher or impact crusher suitable for mill input. After crushing, the suitable stone size is transferred to the MTW, MTM, or LM grinding mill. Barite is powdered in the mill. Finally, the powder is packed and stored. Separation of impurities and impurities from minerals is called processing, which ultimately produces higher purity and more valuable minerals. The barite preparation process is done in the following two ways:

In this method, barite stones are first crushed and then powdered by a ball mill. Second, the produced powder particles are separated from each other due to their specific gravity and then enter the jig through the airflow. At the same time, the airflow constantly hits the powder and disperses particles smaller than 200 mesh with higher quality.

First, barite is washed to remove excess compounds on its surface. At this stage, the barite is changed to smaller sizes by stone crushers to provide the right size for use in milling machines. After grinding, barite particles are stored in jigs. Inside the jigs, some barite particles are separated from the liquid surface and come out of the jigs.

Many factors such as size, processing method, type of packaging, and grade directly affect the price of barite, so these factors should be properly considered before buying barite.

Barite is used as an additive in drilling mud to increase mud quality and density. In general, the temperature and pressure increase significantly as wells are drilled deeper. Barite in drilling mud prevents the release of high-pressure oil and gas. Adding this substance makes the pressure control process better.

Barite is used in the paper industry due to its filling properties.

Since barite does not have a specific color by nature, it can be very effective in producing color. Barite is also used in the production of lithopone. Lithopone is actually a white dye that is 70% barium sulfate and 30% zinc sulfide.

The extraordinary properties of barite make this product useful in the porcelain and ceramic industries. Therefore, the use of this material increases the transparency and brightness of ceramics. On the other hand, the addition of this mineral to the ceramic and porcelain production process makes the bubbles and holes that may have been created in the baking process completely disappear and finally, the final product becomes of higher quality.

About 5% of the barite produced in the world is used in the glass industry. This material is used as a lubricant and glass whitening oxide, which increases the quality, transparency, and brightness of the glass.

As mentioned, barite is one of the high-density minerals. Therefore, it is used in pad manufacturing causing a significant increase in the value of strength and stability of pads. The produced pads are a combination of steel wool, vermiculite, graphite, black carbon, ceramic fiber, resin, iron oxide, barite, and synthetic graphite. The presence of these compounds together and with certain percentages increases the pad service life at very high temperatures or very low temperatures to provide appropriate and acceptable performance.

Barite is used to produce strong, durable, and quality alloys. This mineral makes the produced candle of higher quality.

Barite is used in the pharmaceutical industry because it is a very high swelling, suitable acid absorption capacity, and solubility in water and acid. In the medical industry, this mineral is used as an X-ray absorber. Mostly, this mineral enters the body in different ways and after the radiology process, it is excreted from the body by high water consumption. If this mineral remains in the body, there will be a possibility of damage to the body’s digestive system.

Barium sulfate is supplied as a powder for mixing with water, suspension (liquid), paste, and tablets. The mixture of powder and water and suspension may be taken orally or it may be rubbed and the paste and tablets may be taken orally. Barium sulfate is usually taken one or more times before an X-ray or CT scan.

Barite is often found as concretions and void-filling crystals in sediments and sedimentary rocks. It is especially common as concreting and vein filling in limestone. In places where these carbonate rock units are severely weathered, sometimes large accumulations of barite are found at the contact between soil and bedrock.

Since barite does not have a specific color by nature, it can be very effective in producing color. Barite is also used in the production of lithopone. Lithopone is actually a white dye that is 70% barium sulfate and 30% zinc sulfide.

The extraordinary properties of barite make this product useful in the porcelain and ceramic industries. Therefore, the use of this material increases the transparency and brightness of ceramics. On the other hand, the addition of this mineral to the ceramic and porcelain production process makes the bubbles and holes that may have been created in the baking process completely disappear, and finally, the final product becomes of higher quality.

With more than 20 years of experience, relying on its technical knowledge and expert staff, Kane Aray Sepahan Company has been able to produce barite with very high purity and quality to supply various industries. Compliance with all the necessary standards to produce high-quality products in order to meet the needs of our customers is our main priority, please contact us if you have any questions or requests.

Bentonite and bentonite uses , a type of absorbent and clay-rich rock, has found its way into numerous industries due to its versatile properties. This natural

Introduction But Application of manganese in industry Manganese, a versatile transition metal, plays a crucial role in various industries due to its unique properties. This essay

What is Gilsonite Sealer? Gilsonite sealer, derived from the unique natural resource known as Gilsonite, has become a significant player in the realm of sealcoating for

And what differentiates manganese oxide & rock and Other products of Kane Ara from other competitors. What is the price of manganese here? Why should choose

Multilingual WordPress with WPML