What is bentonite uses?

Bentonite and bentonite uses , a type of absorbent and clay-rich rock, has found its way into numerous industries due to its versatile properties. This natural

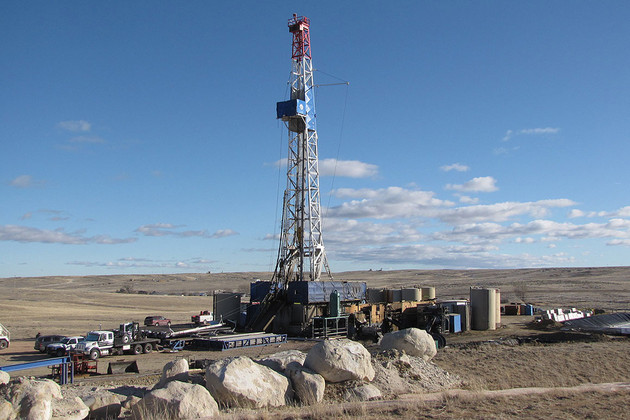

Bentonite, a versatile clay mineral with unique properties, has become an indispensable component in the drilling industry. Its ability to form highly effective drilling fluids and provide stability to boreholes has made it a preferred choice for drilling operations worldwide. In this article, we will explore the different types of drilling bentonite and their specific applications, shedding light on why it is a vital resource for successful drilling projects.

Kane Ara Sepahan is producer of kinds of Bentonite such as:

It should be noted that Foundry Bentonite of Kane Ara is superior in terms of quality and price. Its superiority can compete with the world famous brand like Swellwell

Generally, the placement of atoms in the crystal structure of Drilling Bentonite has caused this material be unique in brittle and unchangeable structure compared to similar metals such as iron. But if the alloy of this material is considered with iron & aluminum and even other widely used metals, it shows that its mechanical and physical properties are improved.

The physical properties of this material are mentioned in the following:

| Yield point/plastic viscosity ratio | 3 |

| Viscometer dial reading at 600 RPM index, ml/2g | 35 |

| Filtrate volume | 14.4 |

| Residue of diameter greater than 75 μm, % | 0.5 |

Sodium bentonite is the most common this type used in the industry. It is characterized by its high swelling capacity and excellent viscosity properties when mixed with water. These qualities make it an ideal choice for creating drilling fluids that provide lubrication, prevent borehole collapse, and facilitate the removal of drill cuttings. Sodium bentonite is particularly effective in stabilizing loose or unconsolidated formations, ensuring the integrity of the borehole.

Calcium bentonite, also known as non-swelling or low-swelling bentonite, differs from sodium bentonite in its lower swelling capacity. While it may not have the same expansive properties as sodium bentonite, calcium bentonite offers advantages in specific drilling scenarios. It is often used in situations where minimal fluid loss is desired, such as drilling through permeable formations or in areas with high groundwater flow. Calcium bentonite can help control seepage and maintain borehole stability in these challenging conditions.

Polymer-modified bentonite is a specialized type of drilling bentonite that has been enhanced with polymers to improve its performance characteristics. The addition of polymers enhances the viscosity and filtration control properties of the bentonite, making it highly suitable for demanding drilling applications. Polymer-modified bentonite is often used in horizontal drilling, where it helps maintain wellbore stability and prevents fluid loss in challenging formations.

When selecting drilling bentonite, it is essential to consider its environmental impact. Many bentonite manufacturers offer environmentally friendly options that prioritize sustainability and responsible sourcing. These eco-friendly alternatives minimize the environmental footprint associated with drilling operations and ensure compliance with environmental regulations.

API (American Petroleum Institute) and OCMA (Oil Companies’ Materials Association) are organizations that establish standards and guidelines for drilling fluids, including bentonite. These standards ensure that drilling fluids meet specific quality and performance requirements.

API standards are widely recognized in the oil and gas industry and are used to assess the performance and suitability of drilling fluids. The API standard for drilling bentonite is known as API 13A. It specifies the physical and chemical properties, including particle size distribution, viscosity, yield point, fluid loss, and alkalinity, that drilling bentonite must meet to be considered suitable for use in drilling operations.

Bentonite and bentonite uses , a type of absorbent and clay-rich rock, has found its way into numerous industries due to its versatile properties. This natural

Introduction But Application of manganese in industry Manganese, a versatile transition metal, plays a crucial role in various industries due to its unique properties. This essay

What is Gilsonite Sealer? Gilsonite sealer, derived from the unique natural resource known as Gilsonite, has become a significant player in the realm of sealcoating for

And what differentiates manganese oxide & rock and Other products of Kane Ara from other competitors. What is the price of manganese here? Why should choose

Multilingual WordPress with WPML