What is bentonite uses?

Bentonite and bentonite uses , a type of absorbent and clay-rich rock, has found its way into numerous industries due to its versatile properties. This natural

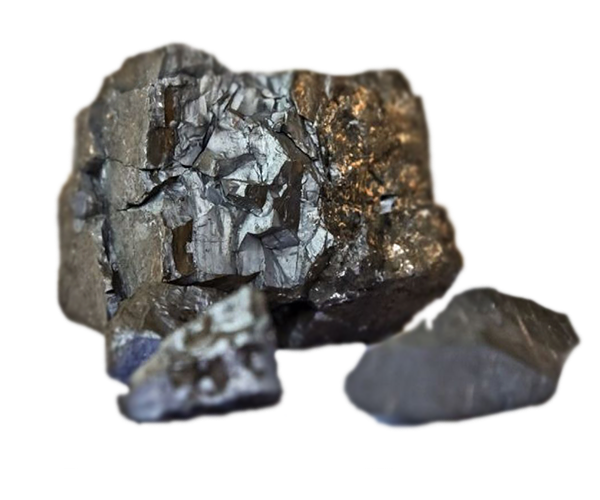

Unlike other minerals, manganese ore exploration is very difficult due to its physical and chemical nature. Maintaining it is one of the most important problems that people face during the discovery phase of this substance. In fact, this metal reacts with the ambient air due to the conditions, and this factor causes problems in the storage of this material. There are various methods to discover manganese mines, the most important of which are geophysics and geochemistry. Geophysical methods are mostly expensive, so they are rarely used, but geochemical methods are an effective method for evaluating and exploring this metal due to their reasonable price and high efficiency.

Kane Ara Sepahan has an exclusive manganese mine

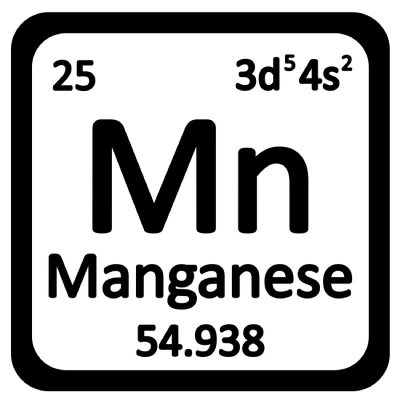

Due to its properties, manganese is one of the most widely used metals in industry. Its structural properties have caused this material to exhibit brittle behavior. This metal is gray in appearance and looks like iron. The nature of this metal is such that it reacts slowly against air and moisture. The ions in this metallic material are mainly paramagnetic and are affected by magnetic fields. This material is mainly known by the abbreviation Mn in the market.

In general, the placement of atoms in the crystal structure of manganese has made this material brittle and unchangeable compared to similar metals such as iron. The alloy of this material with iron, aluminum, and other commonly used metals improves its mechanical and physical properties.

| Mn | 13-18 | 18-25 | 25-32 | 32-40 |

| MnO | 16.8-23.3 | 23.3-32.3 | 32.3-41.4 | 41.4-51.7 |

| LOI | 16-15 | 15-14 | 14-13 | 13-12.4 |

| SiO2 | 33.2-30 | 30-26.4 | 26.4-25 | 25-18 |

| Fe2O3 | 15.8-14.9 | 14.9-13.5 | 13.5-12.1 | 12.1-12 |

| CaO | 10-8.9 | 8.9-6.8 | 6.8-3.7 | 3.7-2.8 |

| Al2O3 | 3-2.7 | 2.7-2.2 | 2.2-1.6 | 1.6-1 |

| MgO | 1.2-1.4 | 1.4-1.7 | 1.7-0.7 | 0.7-0.5 |

| P2O5 | 1.8-1.7 | 1.7-1.3 | 1.3-1 | 1-0.2 |

| Na2O | 0.39-0.47 | 0.47-0.37 | 0.37-0.21 | 0.21-0.09 |

| K2O | 0.9-0.7 | 0.7-0.6 | 0.6-0.7 | 0.7-0.9 |

| TiO2 | 0.12-0.1 | 0.1-0.09 | 0.09-0.07 | 0.07-0.05 |

| BaO | 0.16-0.18 | 0.18-0.2 | 0.2-0.25 | 0.25-0.13 |

| So3 | 0.5-0.45 | 0.45-0.4 | 0.4-0.15 | 0.15-0.05 |

| Sr | 0.12-0.13 | 0.13-0.15 | 0.15-0.16 | 0.016-0.18 |

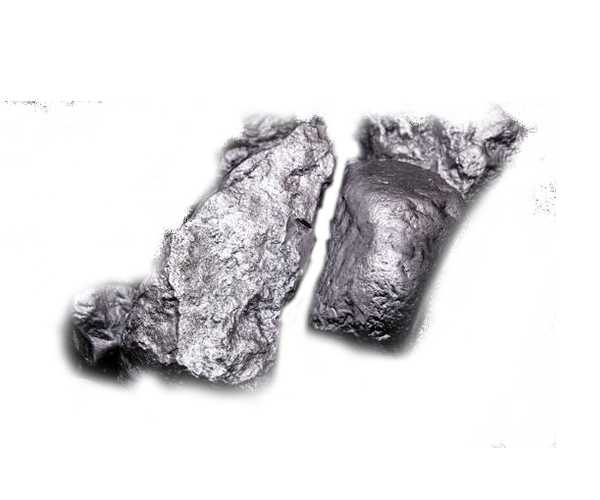

Mainly, the ore extracted from mines, due to the presence of various tailings and differences in physical and chemical properties, and actually due to the presence of impurities, needs to be processed in order to significantly increase the quality of the extracted metal and to be able to use it in Used in various industries. There are different methods for extracting ore from mines, which are mentioned below:

In general, due to their complexity, minerals mainly contain various impurities such as metallic impurities, non-metallic impurities, tailings, and volatile substances.

Some metal impurities are lead, zinc, iron, copper, arsenic, and silver. On the other hand, non-metallic impurities mainly contain substances such as sulfur and phosphorus. The available wastes include silica, alumina, magnesium, barium, and lime, and volatile substances include water, zinc, and other organic substances.

With more than 20 years of experience, relying on its technical knowledge and expert staff, Kane Aray Sepahan Company has been able to produce manganese with very high purity and quality to supply various industries. Compliance with all the necessary standards to produce high-quality products in order to meet the needs of our customers is our main priority, please contact us if you have any questions or requests.

Due to its capabilities and properties, this product is mainly used in the steel industry, so 88% of the demand for this material is used by the steel industry. Manganese is mainly used in the production of carbon steel, stainless steel, and other existing metal alloys such as cast iron and ferroalloys. The combination of this material as an alloy with all kinds of steel increases its hardness, as a result of which its fragility is significantly reduced. The amount of manganese consumed in manufactured steels is as follows:

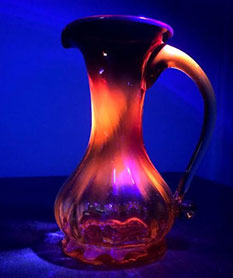

In general, manganese is used in the chemical industry to produce all kinds of chemical fertilizers, manganese sulfate in animal feed, oxysulfate, plant fertilizers, paint, disinfectants, glass industry, glaze colors, etc. Most of the minerals used in these industries must be pure so that the final product has a higher quality.

Other uses of this metal can be mentioned in the battery industry. Mainly in these industries, manganese is used in three forms: natural stone, electrolytic and chemical manganese dioxide. Nearly 10% of the applications of this material in the battery industry are due to the production of dry and chemical batteries, desulfurization, and oxidation. Manganese dioxide is mainly used as a depolarizer in the battery industry.

In general, this material is used in many other industries, including:

Nearly 10% of the applications of this material in the battery industry are due to the production of dry and chemical batteries, desulfurization, and oxidation. Manganese dioxide is mainly used as a depolarizer in the battery industry.

The use of manganese in the chemical industry is used in the production of chemical fertilizers, paint, tile, and ceramic glaze, and the use of manganese tablets will play an important role in the structure of these products.

Other applications of manganese ore are in glass making, which is used as a color changer in dysplastic glasses or as a drying agent in the leather industry. Even some manganese ores become commercial products after mining.

The most important application of manganese in the industry is the preparation of iron alloys as a raw material for the production of cast iron and steel. Manganese is most widely used in the production of steel and non-steel alloys.

With more than 20 years of experience, relying on its technical knowledge and expert staff, Kane Are Sepahan Company has been able to produce manganese with very high purity and quality to supply various industries. Compliance with all the necessary standards to produce high-quality products in order to meet the needs of our customers is our main priority, please contact us if you have any questions or requests.

Bentonite and bentonite uses , a type of absorbent and clay-rich rock, has found its way into numerous industries due to its versatile properties. This natural

Introduction But Application of manganese in industry Manganese, a versatile transition metal, plays a crucial role in various industries due to its unique properties. This essay

What is Gilsonite Sealer? Gilsonite sealer, derived from the unique natural resource known as Gilsonite, has become a significant player in the realm of sealcoating for

And what differentiates manganese oxide & rock and Other products of Kane Ara from other competitors. What is the price of manganese here? Why should choose

Multilingual WordPress with WPML