What is bentonite uses?

Bentonite and bentonite uses , a type of absorbent and clay-rich rock, has found its way into numerous industries due to its versatile properties. This natural

Exploration and extraction of talc deposits in Iran are not very old and go back to 1345. The first talc mine that was identified and a discovery certificate issued for it is the De Musa talc mine. After that, other discoveries were made in the field of talc identification and exploitation, but despite this, no regular geological investigation and exploration were done on any of the country’s talc mines until 2014. In fact, as soon as an acceptable reserve is discovered, then After receiving the discovery certificate, the exploratory operations were stopped and they started exploiting and extracting in an unprincipled manner.

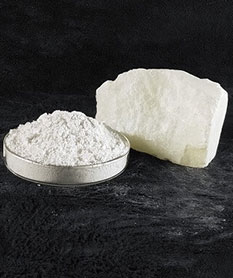

Talc is one of the valuable products in various industries, and due to its features, its scope of application is increasing day by day. This mineral occurs naturally in metamorphic rocks. The properties of igneous and sedimentary rocks change due to extreme temperature and pressure changes in different layers of the earth. Then, due to nearby metamorphism, high-quality magnesium skarns are formed, one of the most important minerals of which is talc. There are different types of these minerals, but according to research, most of the world’s reserves consist of talc schist. This product is formed due to the transformation of mafic, dolomite, and ultramafic rocks at a relatively low temperature. This product is actually hydrated magnesium silicate and due to its composition, it can be seen in brown, gray, white, green, and even colorless colors.

| SiO2 | 51-57 |

| Al2O3 | 3.44-5.14 |

| CaO | 1.3-2 |

| LOI | 7-9.36 |

| MgO | 28-30 |

| Na2O | 0.07-0.4 |

| Fe2O3 | 1.18-4 |

| TiO2 | 0.01-0.1 |

Talc is visible in the form of flat crystals and dense lamellar masses on the monoclinic scale. It is white on small scales and pearl-shaped on large scales. Talc has some iron, aluminum, and calcium in its structure and therefore has great properties. Talc has a specific gravity of 2.8 and a hardness of 1 on the Mouse scale. Talc is made from different plates under van der Waals bonds. This bond has a weak nature and this factor has made talc one of the softest materials in the world. Other important properties of this product include the following:

Roughly crushed rock is transported from the mine to the mill, where further reduction of particles takes place. Impurities are occasionally removed by flotation with skimmers or mechanical processes. This mill produces crushed or finely ground talc that meets the demands of customers in terms of particle size, color brightness, composition, and other characteristics.

The demand for talcum powder is increasing significantly. Among the uses of this powder in various industries, the following can be mentioned:

The use of talc powder increases mechanical strength, surface quality, and scratch resistance in various rubbers, especially sponge latex rubber. On the other hand, the use of talcum powder in plastic materials prevents clogging and adhesion of rubber and plastic in the production process.

The physical properties of talc increase the hardness of some materials such as polypropylene, vinyl, polyethylene, nylon, and polyester in the rubber industry. The low hardness of these products allows the rubber parts to be easily removed from the mold after curing and less damage to them and the mold.

The physical properties of Talc increase the hardness of some materials such as polypropylene, vinyl, polyethylene, nylon, and polyester in the rubber industries. The low hardness of these products makes the rubber parts easily separated from the mold after the baking process and less damage is done to them and the mold.

About 42% of talc powder in the world is used in the paper industry. Talcum powder is added to paper pulp to act as a filler due to its high porosity. This material is used in three stages of paper production, i.e. filling, controlling roughness, and reducing adhesion, as well as paper coating.

Properties such as the appropriate diffusion coefficient, along with the excellent expansion and contraction coefficient, as well as the reasonable price of talc powder, have caused 60% of talc powder to be used in traditional ceramics and thermal insulation. In general, 21% of the world’s talc is used in ceramic industries.

Some properties of talcum powder such as softness, dispersibility, and neutrality have made this material widely used in the paint industry. 8.5% of the world’s talc is used in the paint industry. In general, the use of this mineral due to its low hardness and specific weight in the paint industry increases the quality of produced paint and reduces the depreciation of equipment in production.

Other applications of talcum powder can be mentioned in the cosmetics and health industries. The high moisture absorption property of talcum powder makes using it on the skin of the body to absorb fat and sweat. The softness of this product means that its use in adulthood does not cause skin sensitivity. Due to the delicacy of children’s skin, it is recommended not to use talcum powder in the production of diaper powder.

Talcum powder is widely used in asphalt and bitumen industries. In general, it is used to increase statics, prevent the binding of isogamy-forming rolls, increase stability, and also prevent its decomposition.

The use of talc in painting provides a wide range of paint coverage. In the interior and exterior decorative paints, they act as extenders to improve the hiding power and performance of titanium dioxide. The plastic shape of the talc particles improves the suspension of solids in the can.

Most papers are made from organic fiber pulp. This paste is made from wood and other organic materials. A basic mineral is added to the dough to act as a filler. When the pulp is rolled into thin sheets of mineral material, it fills the spaces between the fibers of the pulp, resulting in paper with a smooth writing surface.

Talcum powder is composed of minerals such as magnesium hydrate and magnesium silicate, which are found in metamorphic rocks. Talcum powder is a widely used powder and one of the softest and most widely used minerals known in the world.

Properties such as the appropriate diffusion coefficient, along with the excellent expansion and contraction coefficient, as well as the reasonable price of talc powder, have caused 60% of talc powder to be used in traditional ceramics and thermal insulation. In general, 21% of the world's talc is used in ceramic industries.

At Kane Aray Sepahan Company, we use the latest technology in the world to produce high-quality products, and we have offered products with various grades to the market. The production process of these products is designed according to the latest standards of the world, so our products are of good quality. For more information and to buy talc, you can contact our experts right now.

Bentonite and bentonite uses , a type of absorbent and clay-rich rock, has found its way into numerous industries due to its versatile properties. This natural

Introduction But Application of manganese in industry Manganese, a versatile transition metal, plays a crucial role in various industries due to its unique properties. This essay

What is Gilsonite Sealer? Gilsonite sealer, derived from the unique natural resource known as Gilsonite, has become a significant player in the realm of sealcoating for

And what differentiates manganese oxide & rock and Other products of Kane Ara from other competitors. What is the price of manganese here? Why should choose

Multilingual WordPress with WPML